- Venjakob

- Noticias y eventos

- Prensa

Informacion de Presa

¿Eres periodista y estás interesado en Venjakob y sus productos?

Aquí puede obtener nuestra información de prensa y fotografías.

08.02.2023 | Deutschland

Reduce to the max

Germany’s most prestigious maker of clocks and clockworks has high demands for the coating solution used for its delicate and highly varied small clock components. The system has to run like clockwork. It has to offer extreme accuracy while also remaining flexible and easy to use. In the search for a suitable system concept, the two long-established com-panies Hermle and Venjakob got together. Leer más...

07.02.2023 | Deutschland

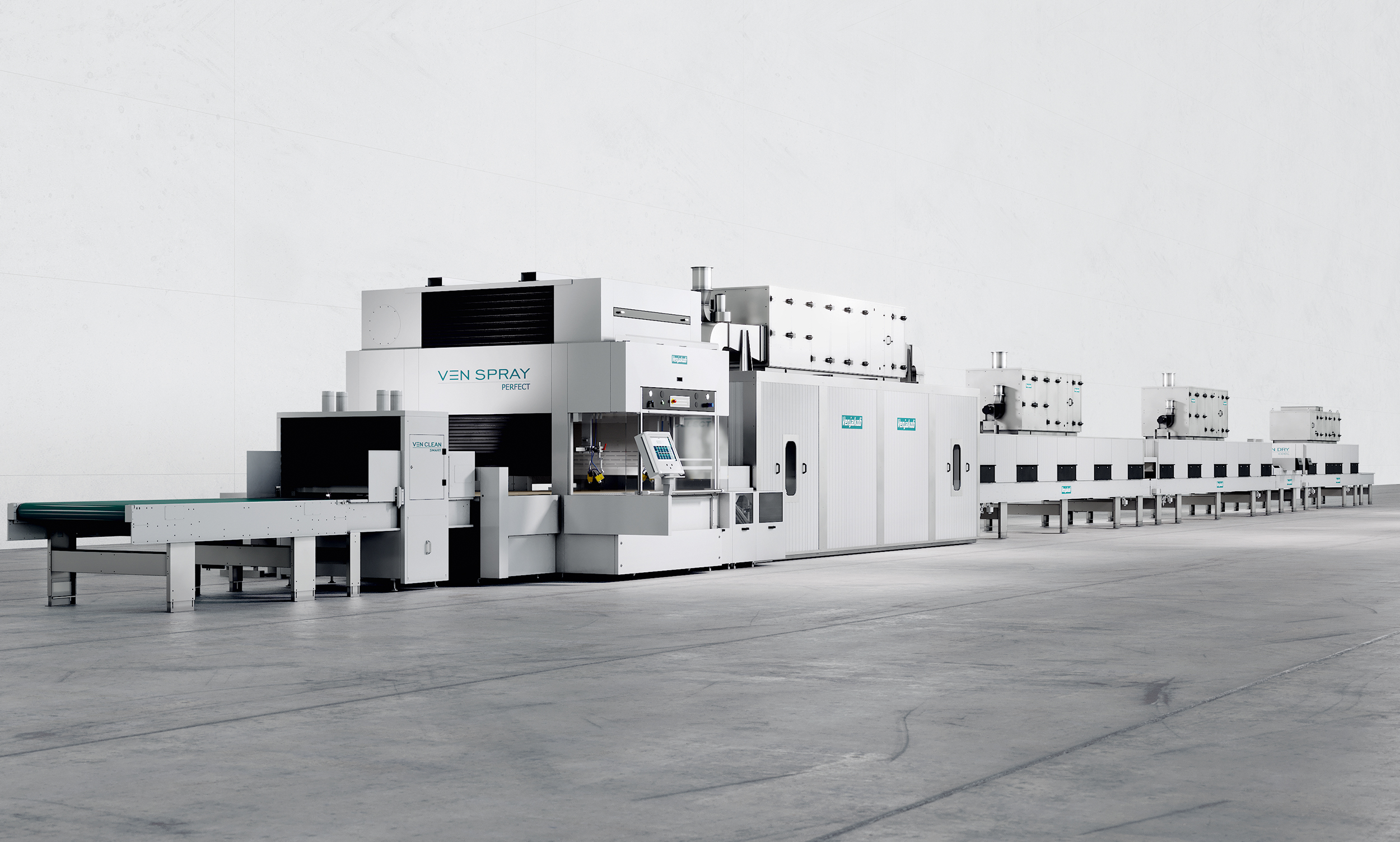

Color variety on a broad front

A good price-performance ratio and design are among the decisive criteria for buyers of brand kitchens when selecting their kitchen. Nolte Kitchens meets these needs with a well-thought-out variety of colors and appealing surface concepts. For this purpose, Venjakob was asked to supply a spray coating system with drying, which also works economically with small batch sizes and saves resources. Leer más...

02.02.2023 | Deutschland

Holz Handwerk 2022

Switch to automated coating easily and cost-effectively VEN SPRAY ONE - especially for craftsmen and small businesses Leer más...More than just stairs

A medium-sized carpenter's workshop in the staircase construction segment purchases an automatic coating system from Venjakob and thus sets a milestone for the future orienta-tion of the family-run business. Individual customer requests in the coating of wooden stair treads can now be realized just as quickly as painting orders for external companies from the interior construction sector. Leer más...

13.09.2022 | Deutschland

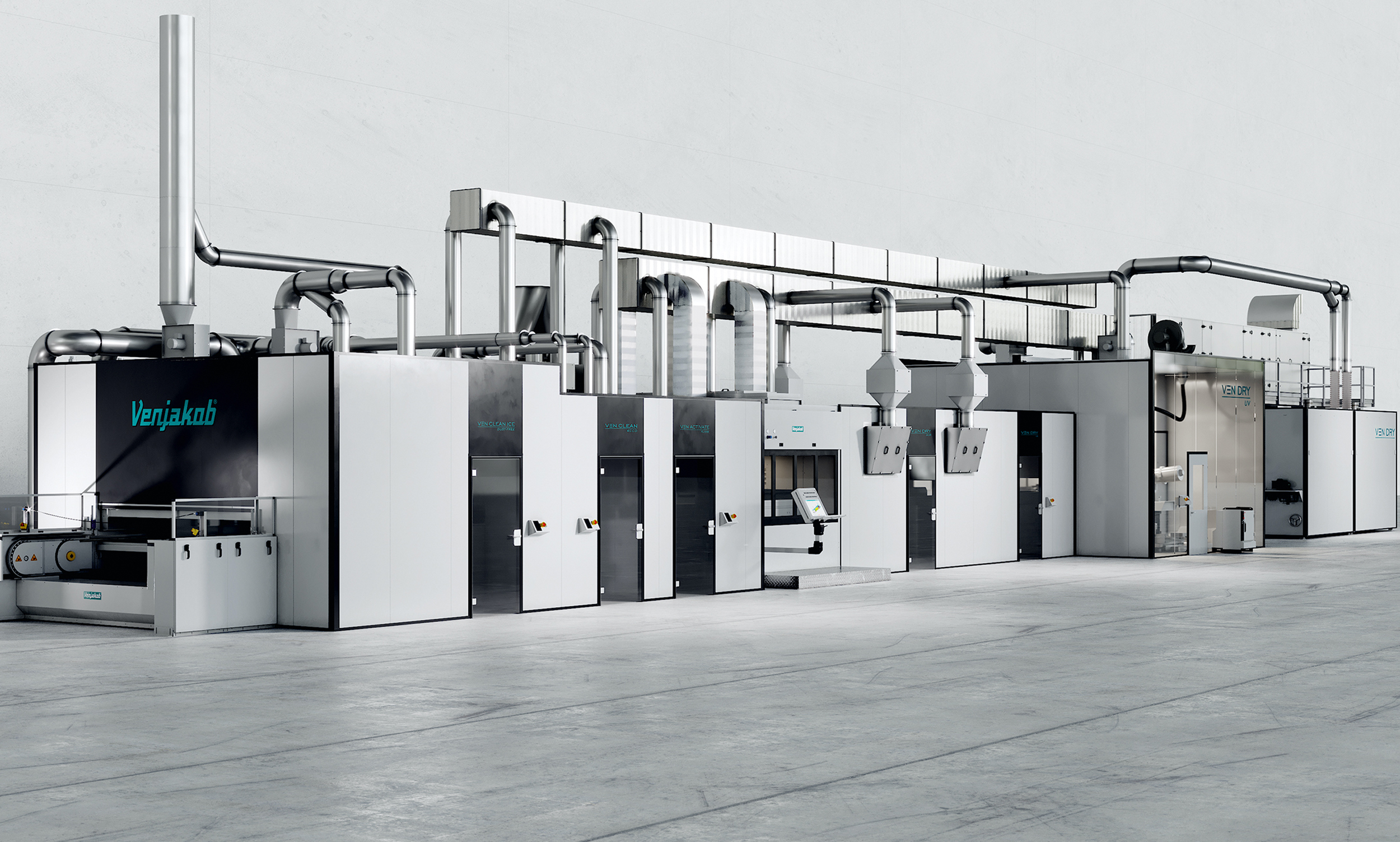

New circulating air system reduces energy consumption

Environmentally friendly and resource-saving coating coupled with a productivity increase requires the use of new or an intelligent combination of patented technologies and processes. For the door manufacturer Garant, Venjakob – as the general contractor – has created a door coating system that relies on a new circulating air process with state-of-the-art spraying technologies. Leer más...

13.09.2022 | Deutschland

Flexibility more important than utilization

Coating solutions for workshops are less about machine utilization and more about flexibility, speed, and reducing the workload of the few employees. Since this year, the Kalmbach joinery has been painting with Ven Spray One – a semi-automatic coating solution. The latest development from Venjakob is geared to the requirements of the skilled trades. The machine's delivery time of only four weeks was another important decision criterion for Stephan Kalmbach. Leer más...

02.02.2023 | Deutschland

Contact-free coating in through-feed operation

The battery cell is the heart of any electric car. More and more German car makers produce their own battery cells - a decision that, among other things, improves their environmental balance. There have been significant efforts to further optimize battery cell production. Venjakob is now con-tributing its own expertise and innovative ideas to this process. The family-owned machine engi-neering specialist has developed a fully automatic plant solution for a German premium car manu-facturer, intended for coating battery cells of different formats in through-feed operation. Leer más...Flexible surface coating for 1000 and one functional door

RWD Schlatter, the Swiss market leader for functional doors in the contract sector, does not focus on standards in volume, but on variety. This variety must be produced in the shortest possible time and in the most diverse quantities – starting from a one door batch - in a customer-oriented manner. Cost awareness, quality aspects as well as a higher flexibility in the production process were decisive reasons to carry out the surface treatment in-house via a modern door coating line. For this purpose, the production hall at the headquarters in Rockwill was expanded and a door finishing line from Venjakob, which was individually adapted to the customer's needs, was set up and put into operation during ongoing production. Leer más...Right on the edge

Because door edges come in a wide variety of shapes, the coating material is not applied by rollers, but by spray coating. During industrial coating, plenty of coating material ends up where it shouldn’t, splattering the door leaf surface and having to be removed with solvent in a highly involved process. JELD-WEN, a major supplier of interior doors, asked Venjakob for their aid in finding a more environmentally friendly solution that would also reduce cost. The result: A reduction of cleaning solvent use by 15 to 20 tons per year. Leer más...Fully automated coupling coating for different requirements

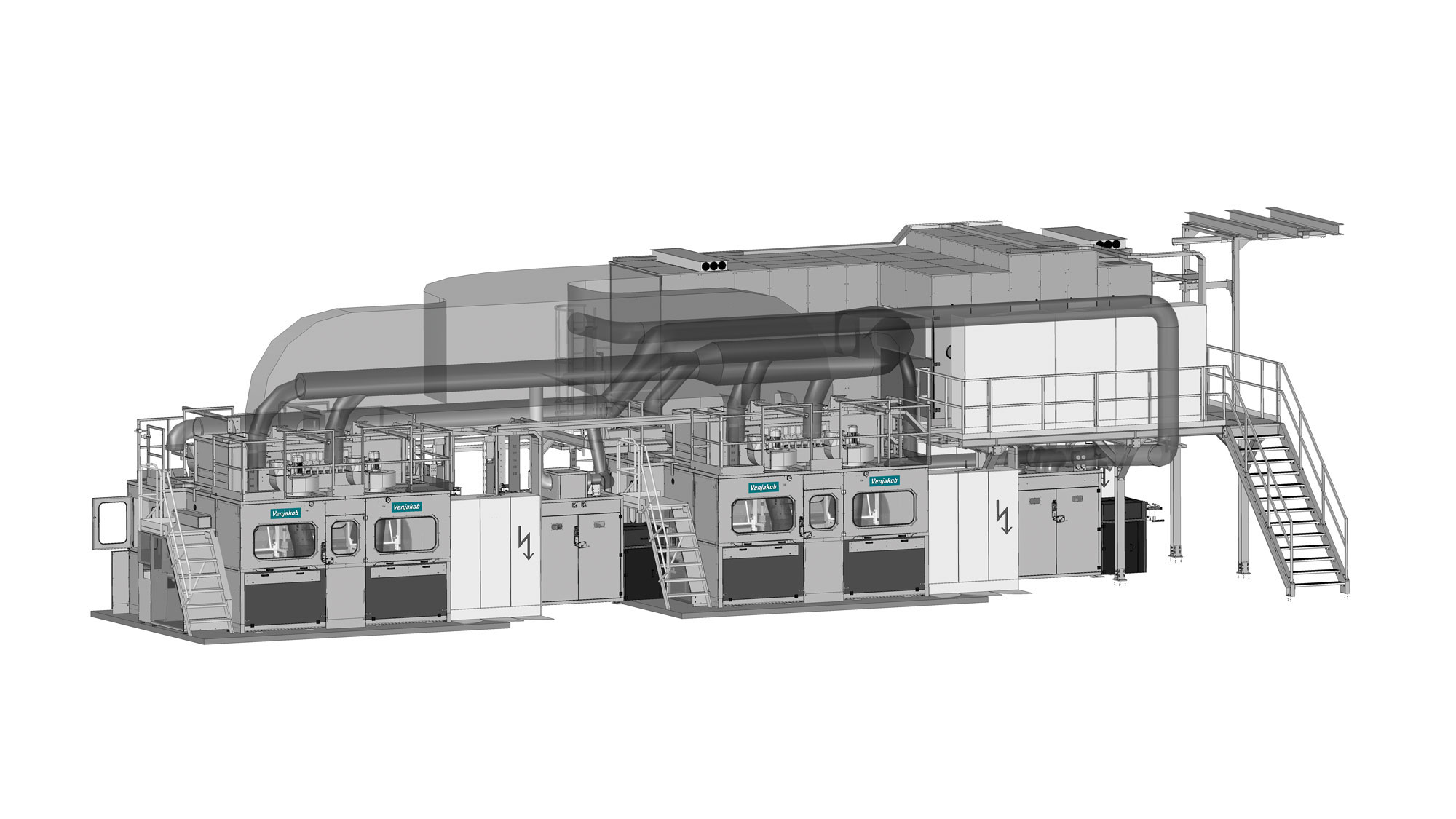

The complex system solution, developed by the German mechanical engineering company Venjakob, fulfils a wide range of criteria for the fast and flexible coating of pipe couplings. It fits seamlessly into the automated manufacturing process of pipeline pipes. Leer más...Tailored coating robot concepts – made by Venjakob

The demand for customized coating systems is on the rise. This has also been clearly apparent to the machine manufacturer Venjakob based in Rheda-Wiedenbrück, Germany, who has gained global renown as an expert provider of surface concepts and conveyor systems. Venjakob has asked users to contribute in the further development of existing coating concepts using robot systems. Leer más...On site worldwide with AR-Service-App

How do you provide fast and professional assistance in the event of complex system malfunctions in times like these, when contacts and travel are limited or are only possible with a great deal of time and effort? "Beam me up, Scotty!" would be the motto on Star Trek. At the machine manufacturer Venjakob, the real-time support works up-to-date via an augmented reality solution. Leer más...Ven Spray One: plug it in and let it paint

With the VEN SPRAY ONE, Venjakob has developed a compact painting machine that is tailored to the needs of craftsmen and small businesses. With the newly designed individual solution, joiners, carpenters and all companies that coat in small quantities can get started with semi-automated coating - quickly and easily at an attractive price. The short delivery time of four weeks also increases flexibility when making invest-ment decisions. Leer más...Three spray coating machines in two quarters - Sweden coats with Venjakob machines

In the course of a year, Venjakob Maschinenbau supplied three spray coating machines from the VEN SPRAY COMFORT series to Sweden. Venjakob, together with its retail partner Jon Stenberg, thus achieved 100% market saturation for spray coating systems in the first two quarters of 2019, according to industry info Maskin Leverantörerna. Leer más...Surface coating of plastic parts - Focus on time wasters

Future-proof painting machines are characterized by economic efficiency and a maximum of flexibility using intelligent control and digitalized communication systems. The modular concept of Venjakob also allows the individual machines to be equipped according to requirements, which can be upgraded with additional functions at any time. Leer más...Fully automatic painting of window components

Painting windows, using the classic method, is a time-consuming process. Venjakob has developed a system concept for the Norwegian company Gilje Tre that allows the coating process to be short-ened rigorously - without compromising quality. Costs are reduced and flexibility in production is increased. The system pays for itself in a very short time. Leer más...Kitchen manufacturer counts on surface expertise

When it comes to spray coating, the Scandinavian premium kitchen manufacturer Kvänum Kök AB relies on the solutions from Venjakob, the mechanical engineering company. Through the perfect combination of existing and new machines, the automated coating system has become a highly efficient complete system that is also flexible. Leer más...Continuous Spray Coating - without stop & go

The magic formula for cost-effectiveness and flexibility in the coating of furniture elements is based on the intelligent interaction of powerful individual machines that are adapted to customer requirements. From cleaning the surfaces to spray coating and drying. The forward-looking modular concept from Venjakob uses all possibilities to create customized solutions. Leer más...Complex handling system for coating pipe couplings

The complex, fully automated coating solution from Venjakob impresses with its easily convertible handling system for processing pipe couplings of different sizes. The well-thought-out handling tech-nology, which is precisely customized to the process steps, enables the fully automatic coating, mark-ing, and signing of pipe couplings in a confined space. This compact design enables short distances and good accessibility to all important system positions. Leer más...VEN SPRAY COMFORT in operation - Coating without language barriers

When it came time to replace its outdated spray coating machine, Ballingslöv, one of Sweden’s leading manufacturers of premium kitchens, decided to collaborate with the German system manufacturer Venjakob Maschinenbau. Within two weeks the new coating machine VEN SPRAY COMFORT was up and running. And it was accomplished without any language barriers—since the Ven Spray Comfort can be operated in multiple languages. Leer más...

19.08.2021 | Deutschland