Holz Handwerk 2022

At this year's Holz-Handwerk in Nuremberg, Venjakob Maschinenbau will focus on the VEN SPRAY ONE. As a sensible replacement, or as a supplement to your hand-held spray booth and the growing demands for reliability and quality, Venjakob Maschinenbau offers an interesting alternative with the VEN SPRAY ONE model.

The compact spray coating machine is specially designed for the needs of entry-level users. The extra-large touch screen and the self-explanatory user interface of the control make machine operation easier.

The stand-alone solution has an integrated control cabinet. This means that commissioning can be carried out quickly and easily, which saves installation costs and time. The solid and inexpensive technology convinces the users of the performance and surface quality produced.

The entry-level model is in no way inferior to the professional range in terms of design and energy efficiency. It also has a large-volume spray booth and long-lasting, energy-efficient LEDs. The VEN SPRAY ONE is designed for the use of 4 spray guns. In order to achieve reproducible quality, recipes can be stored in the system control and called up quickly and easily. The cleaning effort of the coating machine is very low, it is equipped with a paper belt transport.

With its new coating system, Venjakob would like to meet the requirements of carpenters and craft businesses.

The time has come to break new ground. Those interested can find out more about the VEN SPRAY ONE on display at the Holz-Handwerk in Nuremberg in Hall 11, Stand 201.

Future-oriented coating technology:

energy-efficient + high-performance.

Furthermore, Venjakob invites to rethink coating processes.

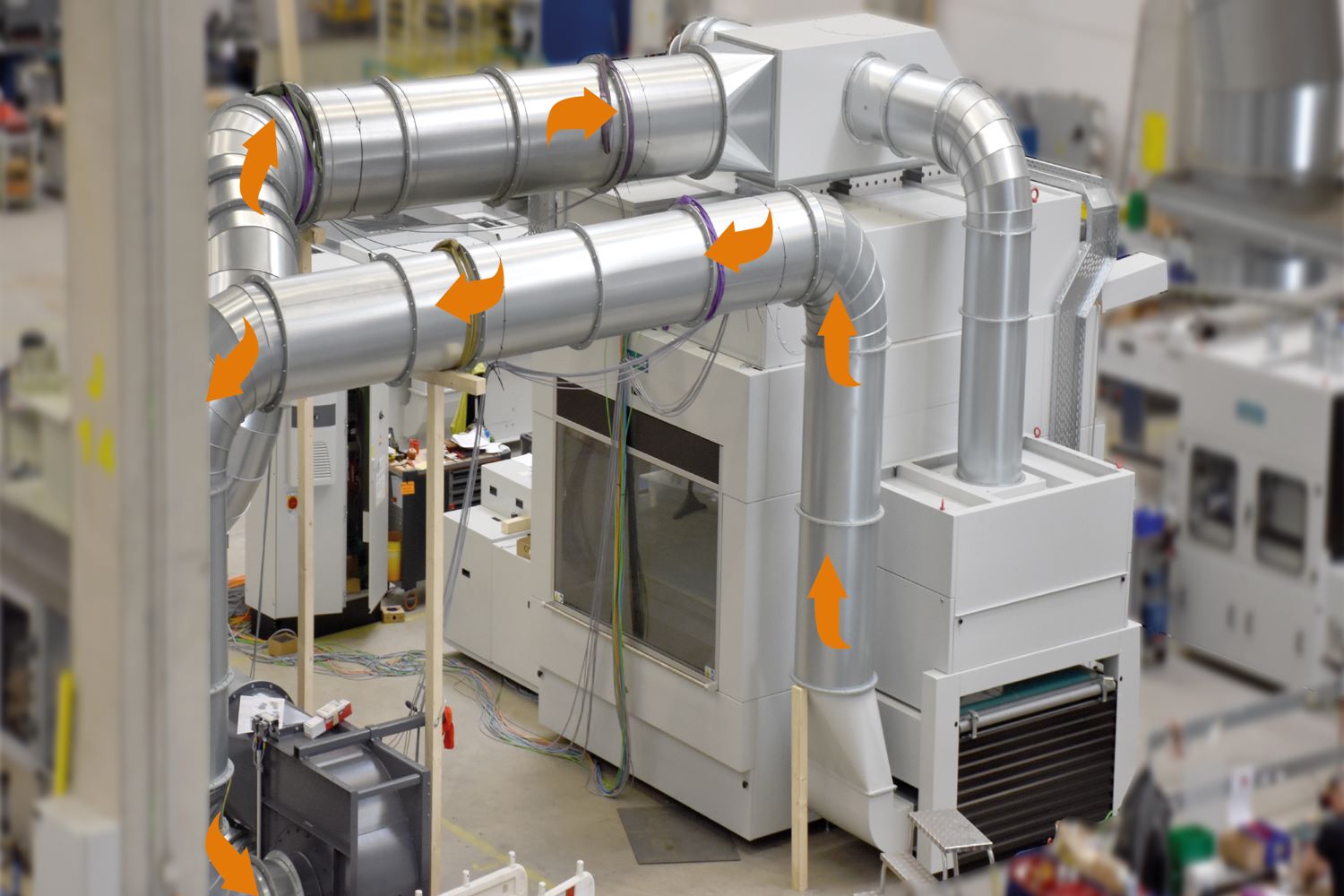

Resource shortage, environmental protection and sustainability are buzzwords that are on everyone's lips. Venjakob is happy to take up these topics at the trade fair and provide information on what the company has done to optimize users' production processes with its technology. For example, by installing an innovative, resource-saving recirculation system in the large-capacity booth of the VEN SPRAY PERFECT spray coating machine; for the application of water-based coating materials. This has proven to save heating energy and reduce environmental emissions. An integrated air humidification system for highest coating quality with low energy consumption.

The experts for surface technology are looking forward to interesting requirements in the course of the exhibition. Venjakob will be happy to discuss individual approaches to solutions, or to present realized projects. As, for example, for the construction elements and building materials industry, for which the family-owned company is a reliable partner. For the staircase manufacturer with batch size 1 as well as for the industrial door coating with feed rates of up to 20 m / minute.