Complex handling system for coating pipe couplings

The Russian company OMK Vyksa produces a wide variety of pipes, such as for the construction of oil, gas, and water pipelines. Gigantic pipeline projects in more than 20 countries around the world are equipped with pipes from OMK Vyksa. The company wanted to manufacture the pipe couplings it had previously bought in its own factory. This will not only cover their own needs, but also offer the entire product range to their customers from a single source.

Short distances for maximum efficiency

For this project, a new production hall was built in which a modern production line for the manufacture of pipe couplings of different sizes was implemented. Two fully automatic coating lines from Venjakob for coating, marking, and signing pipe couplings fit in seamlessly on an area of 15.8 x 29 meters. These cover the entire range of different pipe coupling sizes. “When planning the new system technology, it was important for us that all manufacturing processes take place in one hall. Short distances for maximum efficiency. The engineers at Venjakob met this important criterion with this compact system, ”says Dimitriev Alexander Michailowitsch, project manager at OMK Vyksa.

Automated coating every second

A custom system solution, in which Venjakob is a specialist in surface coating processes, but also competent and experienced in the planning, development and implementation of fully automated conveying and handling concepts for maximum cost-effectiveness. The entire coating process - from loading at the loading station through the individual processing stations to unloading - takes place without external intervention. The system is designed for a wide range of pipe coupling types that can be coated both externally and internally. The complete processing time depends on the dimensions of the pipe coupling and takes between 16 and to a maximum of 60 seconds.

Transport system adapts automatically

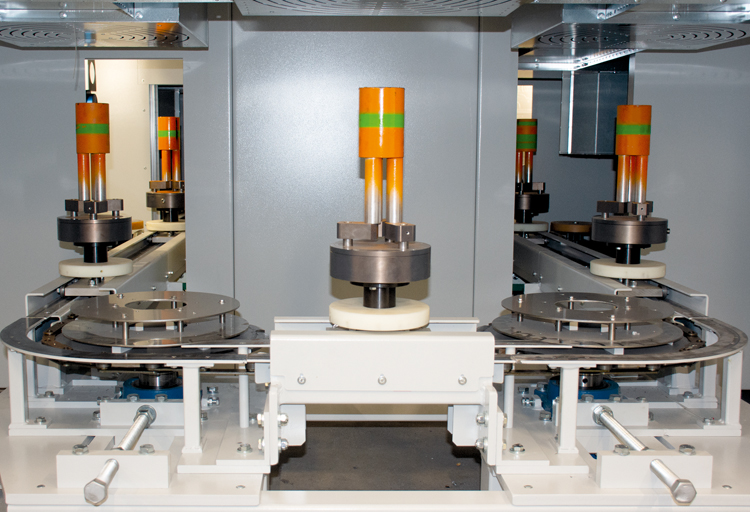

A particular challenge lay in the variability of the pipe coupling types. This required a certain degree of system flexibility, both in the coating process and in the handling system. “The fully automated handling had to be designed for at least 20 different pipe coupling diameters and it had to be easy to convert to each of these diameters,” reports Kornelius Berg, sales engineer at Venjakob Maschinenbau. This requirement could be solved via the control system. The machine operator selects the corresponding diameter of the coupling using a program. After the selection, the entire transport system automatically adjusts to the coupling size. Only the workpiece carriers for the inner and outer coating and the gripping systems for loading and unloading are converted manually. “These were designed in such a way that they are infinitely adjustable. An exchange of centering attachments or discs is not necessary. That saves a lot of time,” emphasizes Kornelius Berg.

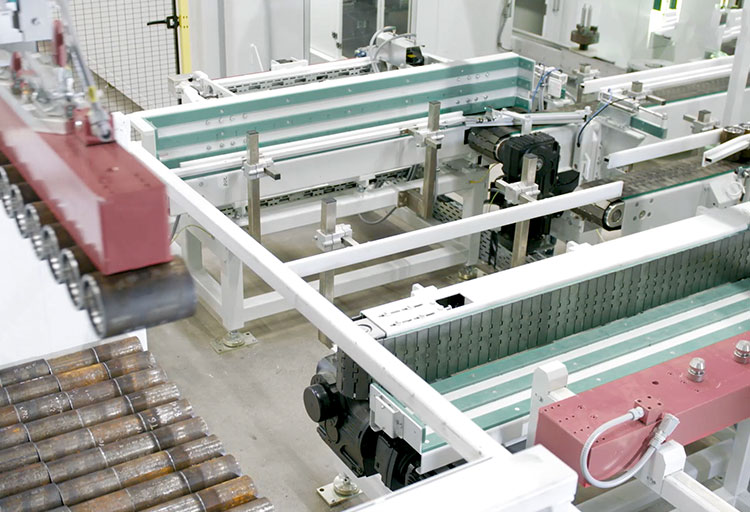

Loading and unloading in continuous flow

A second important requirement for the planning of the entire system had to do with the capacities of the installation area. For the optimal process flow, it is necessary that the employee who delivers the coupling container with the forklift for loading can pick up the finished coated coupling again at the same place. For this, the loading and unloading portals were arranged side by side. The couplings to be coated are fed via a turning station to the transport system for the inlet and the finished couplings are fed via a further turning station to the transport system for the outlet, which leads to the removal portal on the opposite side. This enables continuous loading and unloading.

The Process

Loading and placing couplings on workpiece carriers: In the first step, the pipe couplings are automatically arranged in a container in several layers one above the other. The couplings are removed from the container in rows, placed on the turning station and then placed vertically. The loading and unloading can be done with a magnetic or fork gripper. The onward transport to the loading portal takes place via a chain transport system. From here the pipe couplings are placed individually on the workpiece carriers. These can be infinitely adjusted to the required size of the pipe coupling - the spindle mounts are closer or wider together.

Coating, marking, and signing process in a closed system: The preheating, the outer and inner coating as well as the hot air-drying take place in closed systems on a spindle chain conveyor. The couplings travel over a drying section between the individual coating processes.

Internal thread is protected from corrosion: After the external coating has been completed, the pipe couplings are placed on the workpiece carriers for the internal coating. Here the couplings are placed on another spindle chain conveyor for the internal coating. Thread protection is also carried out in a closed system with an oil-water emulsion.

Unloading and loading right next to each other: After the subsequent warm air-drying, the finished pipe couplings are placed on the discharge conveyor belt and fed to the turning station for collection. In the last step, the turned couplings are placed in rows in several layers in the unload container using the magnetic gripper.

Special features of the overall system

- Fully automated handling

- Flexible design for different pipe coupling types

- Automatic conversion of the transport system

- Infinitely adjustable conversion of workpiece carrier and gripping system

- Loading and unloading portal side by side

- All-important system positions are easily accessible

- Low maintenance system

- Seamless integration into the entire manufacturing process

- Compact, modular design