DIP coating

Dip coating a powerful alternative application technique

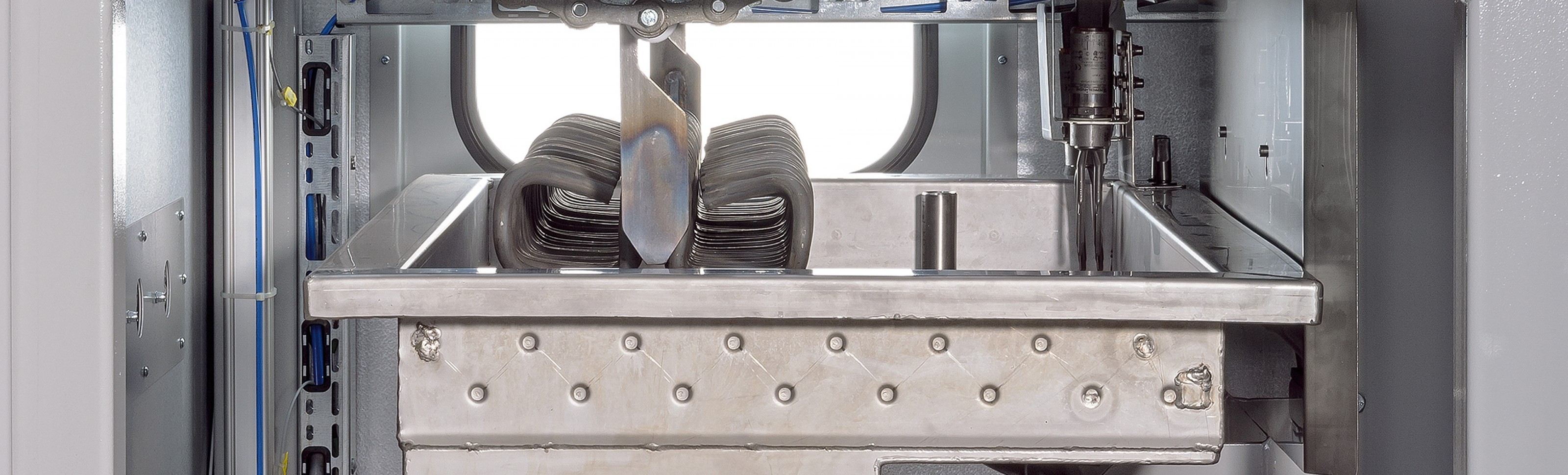

Our dip coating plant is designed for the application of wet paint systems. In Venjakob dipping, workpiece carriers with workpieces are dipped and not - as is also usual alternatively - poured as bulk material into a dipping basin/drum. The workpieces to be painted are conveyed in a suspended position.

What distinguishes our system concepts

Our dip coating systems allow you to easily and effectively coat your metal and steel parts. Dip coating also promotes high throughputs and an efficient degree of application. Depending on a variety of factors such as the structure of the material used, the coating medium that drips off can be reused to a certain degree, which in turn conserves resources. Built to be high-quality, our systems require minimal maintenance and offer high system availability. The size of the dip coating system is dependent on the coating medium, the equipment, the size of the workpiece, and the loading unit.

The system can be loaded manually or automatically and in accordance with the workpiece flow upstream and downstream. Venjakob can offer you a variety of handling technologies and conveyors from its own production range. We can also tailor any additional system modules such as drying oven or supply system to your specific requirements.

- application

- area of application

- Process flow

- advantages

application+

Applications dip coating

- Water based coatings

- Solvent based coatings

area of application+

Areas of application

- Steel parts

- Metal parts

Functional coatings are applied, which for example act as corrosion protection, or decorative coatings to enhance the value of the workpiece.

Process flow+

Description of the dip coating process

- Loading with individual parts or parts on part carriers via a customer-specific feed system, robot, or by hand

- Conveying via chain conveyor or specific conveyor system

- Dipping via portable dip tank

- Dripping off in drip-off position with return to the dip tank

- Drying in the integrated drying tunnel, adapted in line with the coating system

- Removal via either the feed system or a removal system, robot, or by hand

To ensure reproducible results, the level of the dip tank is regulated to maintain the same quantity of coating medium at all times. Depending on customer needs, our dip coating systems also come with additional features that make it easy for system operators to work with the technology. The system that supplies the coating medium can be equipped with an optional level indicator, for example, or even a stirring unit that circulates the coating medium to prevent it from depositing. If you need to prevent excessive diffusion of the liquid in the coating, we can help here, too, with our patented Coolac® technology.

advantages+

Benefits

- Esimple machine for high throughputs

- Application efficiency of nearly 100%

Your contact person

There are many options for simplifying and optimizing your processes. Simply speak to our experienced project managers. Our employees would be happy to work with you to develop a concept that exceeds process requirements and makes your production more economical.

Allow us to advise you on potential systems in a personal meeting with our competent representatives.