Blasting machines

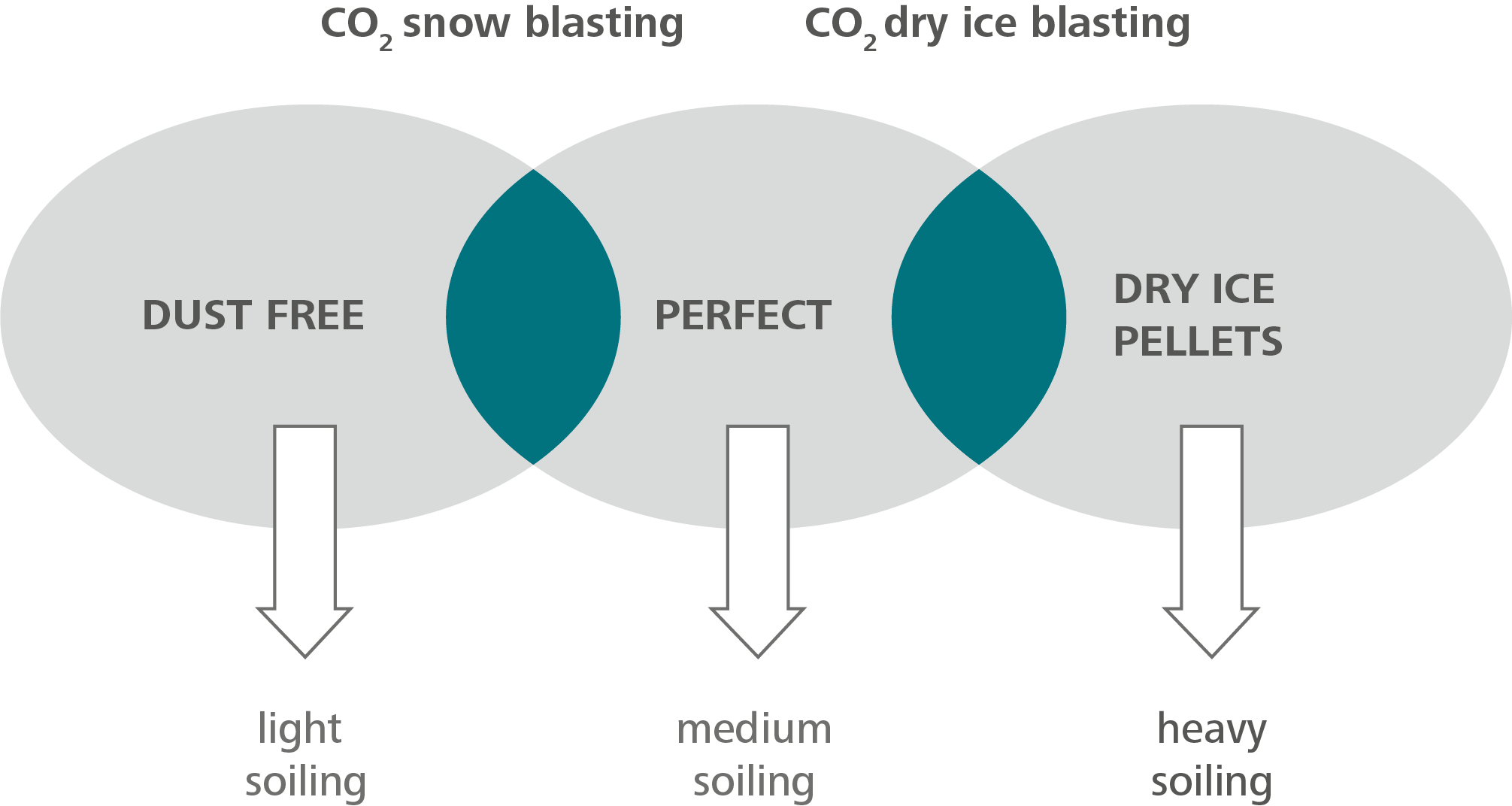

We have the solution for your cleaning problem: CO2 Snow Blasting and CO2 Dry Ice cleaning

This technology can be used as a stand-alone solution or installed upstream into existing processes. This process guarantees residue-free cleaning of components and thus flawless coating.

Venjakob Dry Ice cleaning for perfectly cleaned surfaces

Whether CO2 snow blasting or CO2 dry ice cleaning, our blasting systems represent perfection down to the smallest detail, from small 3D parts to large workpieces in large batches. Our blasting systems are suitable for any application. CO2 cleaning can be used as a stand-alone solution or installed upstream into existing processes. The process achieves residue-free component cleaning and thus enables a flawless surface for subsequent processing such as coating.

- Procedure

- area of application

- advantages

Procedure+

CO2 - Dry Ice Cleaning

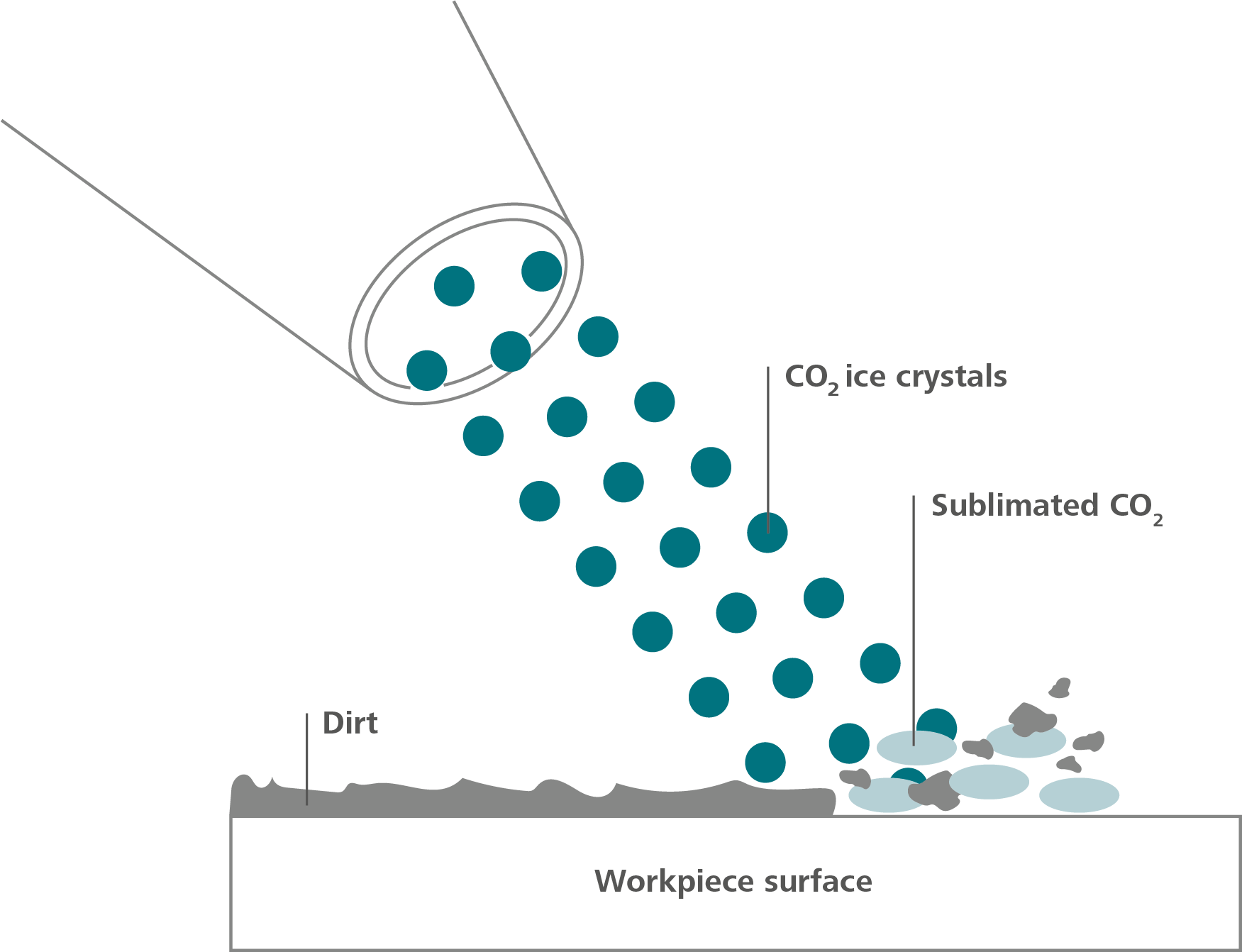

Dry ice cleaning uses solid carbon dioxide – dry ice – as its blasting medium. Dry ice cleaning works in a way that’s comparable to abrasive blasting or hydroblasting. Solid CO2 pellets (solid carbon dioxide, often referred to as “dry ice pellets” are used rather than water, sand or other abrasive materials. Made from a mixture of compressed air and dry ice particles, the cleaning jet hits the surface to be cleaned at high speed.

CO2 - Snow blasting

A cold burner produces its own dry ice from liquid CO2. The cleaning blast consists of a mixture:

- CO2 snow particles

- CO2 gas that’s not converted into particles

- Compressed air

area of application+

Applications of dry ice cleaning

- Metal

- Plastics

- Glass ceramic

- Building materials

advantages+

The benefits and features of Venjakob CO2 cleaning units

- The intensity of cleaning can be tailored to the process

- Applications from manual to fully automatic

- Suitable for large-surface cleaning before the coating or adhesive process

- Can be installed on surfaces or in robot systems

- Can be integrated into existing system technologies with high flexibility

- Reliable continuous operation

- CO2 consumption defined through permanently installed volume adjustment

- Wear and icing-free

- No formation of water condensation

- Fast switch-on and off times for operation cycles

- Reduced space requirements

CO2 snow blasting speaks for itself. With the quality somewhere between CO2 cleaning and high-performance dust removal, this system variation offers optimal pretreatment with sound insulation measures and simple part fixture.

Your contact person

The processes can be tested under practical conditions in our in-house laboratory. Tell us your requirements profile, involve your material supplier and we will work out a solution together with you.