- Venjakob

- System Engineering

system Engineering at the highest level

Starting with consulting and planning proceeding with project management and machine production up to final assembly and start-up, Venjakob takes responsibility for each step during our affiliation with your company. Our team at Venjakob North America listens to your demands. We start by working out a tailormade solution for your specific needs. We are in close communication with the German headquarters, who offers the performances listed below.

Traditional mechanical engineering, since 1963. Well proven, innovative and powerful.

You can experience the power of the entire group and the “first class” and fast support and consult from Venjakob North Americas Sales and Service team.

Cutting-edge system engineering

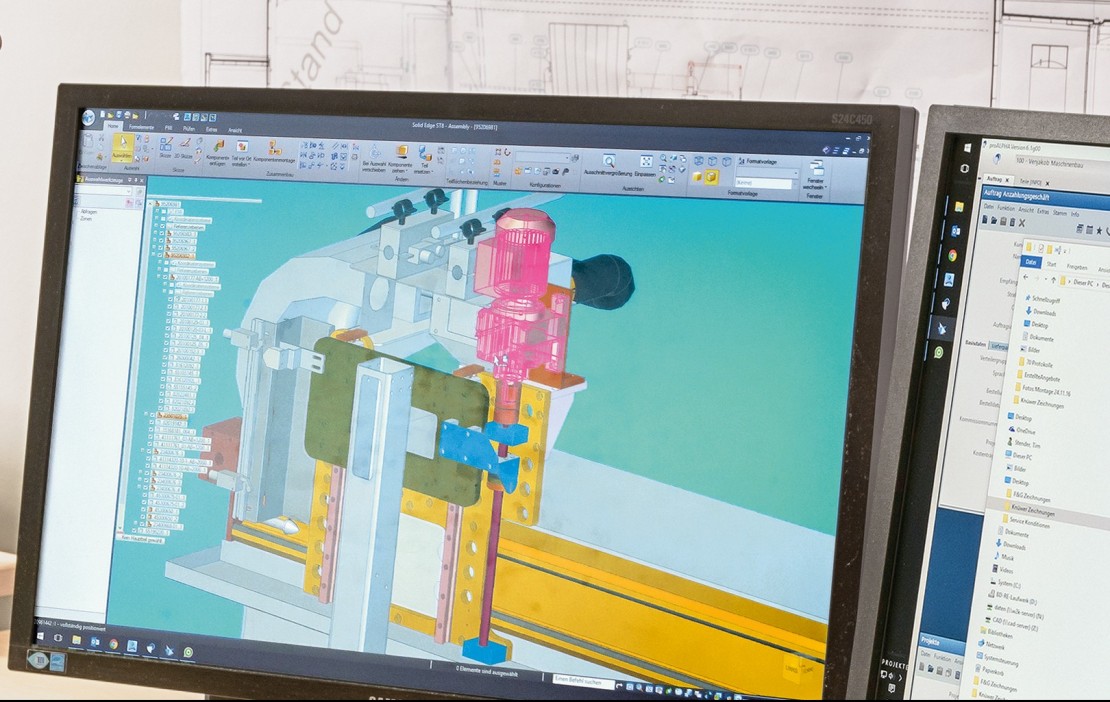

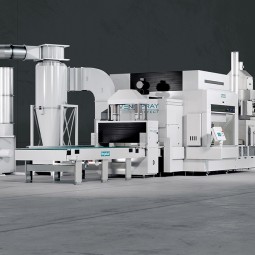

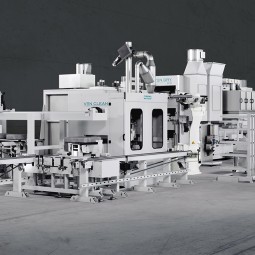

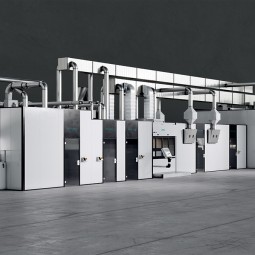

In a space measuring 25.8334 square foot in Rheda-Wiedenbrück and Saarstedt, Venjakob mechanical engineering manufactures industrial systems and special machinery in accordance with our customers needs. Thanks to our decades of experience, we can provide tailored systems and implement individual solutions in system engineering and surface technology. Our process technology developed in-house and state-of-the-art 3D system simulations allow us to present the design with an outstanding level of detail. The result is high-quality components that are guaranteed to be error-free for turnkey industrial systems. An experienced project manager oversees and, with the aid of modern process management systems, coordinates each of our customer projects for the purpose of quality assurance.

Future-proof solutions

In addition to manufacturing innovative and forward-looking system engineering solutions, we ensure that our customers receive exceptional mechanical engineering advice, which always includes clarification of the following topics:

- Environmental protection

- Safety

- Noise and fire protection

- Emission laws

Special mechanical engineering and tailored system technology

Our core area of expertise is clearly system engineering. From planning and manufacture to commissioning at your location, we assume responsibility for everything ourselves. But our range of services also includes electro technical work. We have outstanding expertise in electrical design, switch cabinet production, and the wiring of the machinery and systems we manufacture. Thanks to our in-house welding shop and coating machine and extensive stock of various general and construction components, we can drastically reduce production times and complete orders in no time at all.

Even when it comes to automation, our customers can rely entirely on our modern solutions. Whether it’s in the field of industrial coatings, for special machinery, or in traditional system engineering, our internally developed PLC programming can be used to fully automate production line processes, leaving nothing to be desired for our customers. Our precision and quality standards require us to develop exceptional comprehensive solutions, including the preparation of layout, foundation, and media plans for your finished machine. From traditional coating machines to one-of-a-kind special machines and from our production facilities in Rheda-Wiedenbrück and Sarstedt to that in Strongsville, Ohio, the Venjakob Group’s excellence service guarantees your mechanical engineering project is in good hands.

We’ll be happy to advise you in a personal, comprehensive consultation on our services and potential systems. Simply give us a call or send us an E-Mail!